Door industry equipment rolling shutter door forming machine for sale

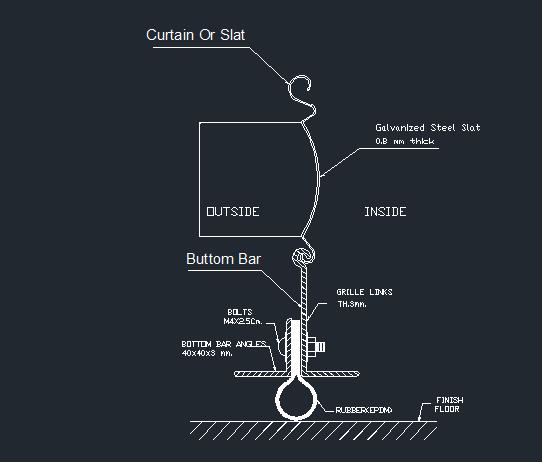

1, Rolling shutter door slat equipment for producing steel curtain frame

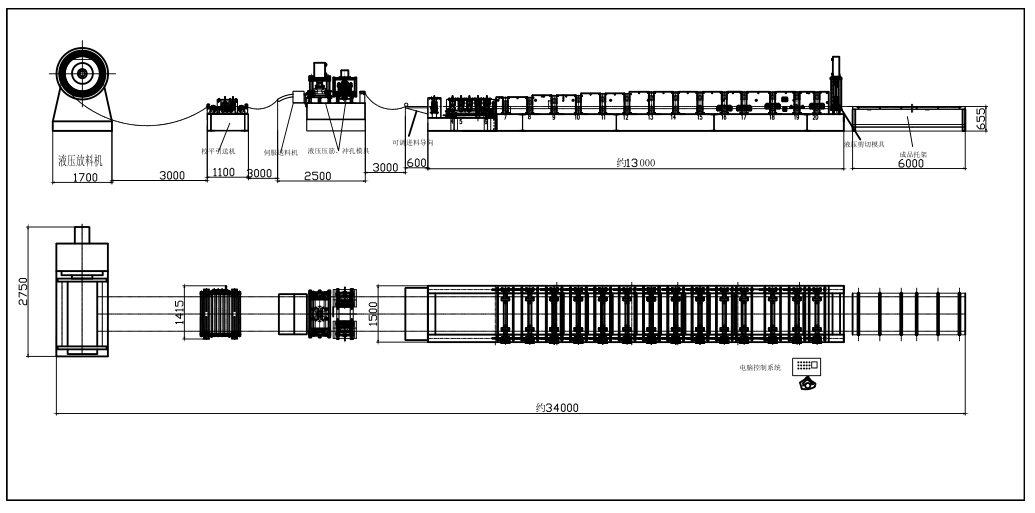

2,Completed shutter door slat production line working flow ,

Decoiler —guiding — feeding — hydraulic punch— roll forming — finished product

factory production layout for reference.

3,Equipment consists

The equipment consist with de-coiler , leveling machine, servo feeding

machine, main forming machine, cutting device, collection table .PLC control system

4,Main technical parameter of production line ,

material : GI steel sheet, low carbon steel.

the thickness of the steel sheet , 1.5mm

inner diameter of coil , Φ508mm

line speed, 8-12m/min ( adjustable)

5. The characteristic of the machine

5.1 Metal strip coil de-coiler ,

functional and structural features,

be used to support and expansion steel coiler , section steel welding fuselage. it is easy to operate.

technical parameters

material inner diameter : φ508mm

range of inner diameter : ф450-550

maximum outer diameter: φ1200mm

load capacity: ≤ 5T

5.4 Servo feeding machine

Type : servo feeding

Functions and Structure: Pinch and be with steel to the press machine. Polyurethane roller ensure that the feeding force. Feeding each error of feeding be controlled in rang of ± 0.15mm. Compared with the servo Clamp, feed length setting is more flexible, adapt to a wider range. This feeding device is more suitable for wide material , can effectively improve the feeding accuracy. Servo motor, measuring devices, digital control system are the imported components.

technical parameters:

maximum number of feeding: 30 ~ 40 times / min (adjustable)

feeding step: 100MM / step (adjustable).

5.5 Hydraulic hole punching system

Function:Hydraulic punch hole (Mould 1 set)Structure: set the length, automatic length measurement, automatic positioning reaches the set distance stop action , hydraulic cylinder driven punching die, stamping automatic shutdown.Hydraulic system working pressure:16MPaHydraulic station:5.5KW( Hydraulic punch hole/shear use same station)

5.10 Forming machine :

type: double cantilever gear drive, width adjustable universal forming machine and the overall mobile, fast (waist height and width) exchange specifications.

Forming Roller:16 stations,and add Rub-roll, To make sure the surface profile no scratches.Side Panel:T.18mm ,A3 steel Heavy duty 。

Rolling speeding: 8-12 m/min。

Roller material:#45 bearing steel,overall quenching, hardness HRC56-62 ℃. Motor power:5.5KW。 Main Roller :¢75mm,45 #。Equipment base: 35 # H type using welded steel plate.Transmission: chain drive.Security: across the board with emergency stop buttons, easy to handle emergencies, to ensure that equipment and operator safety. And other gear in the chain and the staff could easily lead to injury transmission section covered with protective cover, to ensure the safety of workers.

5.11 Collection table

type: Finished cable tray arrive collection table, worker will collect products , non-powered roller.

function and structure: consist of section steel (square pipe), no power roller assembly, welding, play a role in supporting finished product ,can adapt 8-meter finished product.

5.12 Electrical control system

the whole line adopt imported PLC control , touch screen be used for human-machine interface, achieving the interaction between man and PLC.